In the ASTM acceptance standard for testing rubber surgical gloves (D3577) and rubber medical gloves (D3578), made of latex, vinyl, and nitrile. The standard describes the standard size, material properties, physical and mechanical property acceptance levels, aqueous protein and antigen protein content, and visual inspection required for a glove to be used in a medical procedure. Other relevant standards include ASTM D6319, ASTM D5250, EN 455-2, ISO 11193-1:2002, and ISO/AWI 11193-2.

How to perform ASTM D3577 Medical Elastomer & Rubber Glove Test

Topics: ASTM Tests, rubber, Plastic, Tensile Test

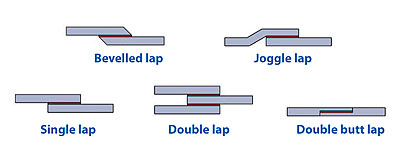

How to Perform an Adhesive Lap Joint Shear Strength Test - ASTM D1002

Topics: ASTM Tests, Tensile Test, Adhesive, Shear

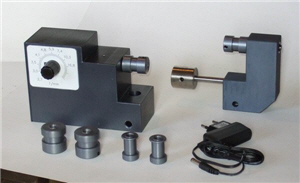

ISO 594/1 - Torsion Testing Equipment -Torque, Axial Load

ISO 594/1 describes dimensions, testing profile, and parameters for testing conical fittings with a 6% (luer) taper for hypodermic syringes, needles, and certain other medical equipment, such as transfusion and infusion sets. This standard covers rigid and semi-rigid materials for gauging and performance.

Topics: ASTM Tests, Biomedical, Torsion, Biaxial, delivery device

ASTM F1264 Annex 3 is a test method for bending fatigue testing of intramedullary fixation devices (IMFD). This cyclic 4 point bend test determines the fatigue life at a specified bending moment or estimates the fatigue strength for a specified number of cycles.

Topics: ASTM Tests, Biomedical, Bend Testing, Fatigue. implants

How to Perform an Adhesive Loop Tack Strength Test - ASTM D6195

Topics: ASTM Tests, Plastic, Adhesive, Packaging, Film

How to Perform a Rubber & Elastomer Tear Strength Test - ASTM D624

The tear strength of thermoset rubbers, thermoplastic elastomers, and silicones can be measured according to specification ASTM D624. The test measures the strength required to initiate a tear in a material. D624 describes multiple different types of sample shapes that can be tested in a standard universal testing machine (tensile testing machine). Usually materials that are tested to D624 are also tested according to specification ASTM D412 to measure the tensile strength and elongation. If you are going to perform this test, you should read the entire specification from ASTM. This is a quick summary to decide if this test is right for you, and to point out what equipment you need to perform the test.

Topics: ASTM Tests, rubber, Plastic, Tensile Test, Packaging

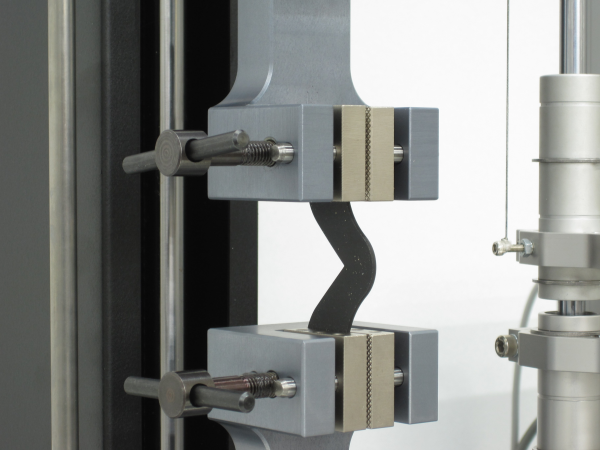

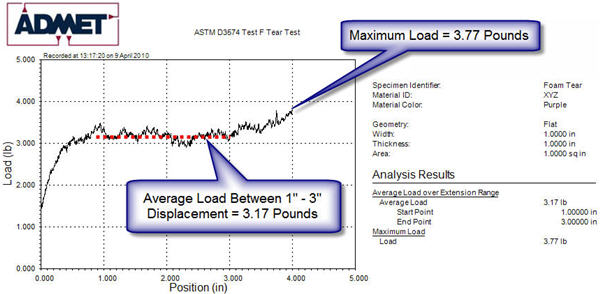

This article discusses how to perform a polyurethane foam tear strength test on a universal testing machine (polyolefin foams are tested similarly). Complete instructions for a foam tear strength test can be found in ASTM D3574 Test F which applies to slab, bonded, and molded flexible cellular urethane foams. There are many tests in this specification including tests for density, ball rebound, airflow, etc. However, the most common tests in the specification are the mechanical tests that can be performed on a universal testing machine such as indentation force deflection, compression force deflection and tensile strength. This article discusses Test F, the foam tear resistance test.

Topics: ASTM Tests, Tensile Test, Packaging, Foam

How to perform a foam tensile strength test - ASTM D3574

The purpose of performing the tension test on polyurethane foam is to measure the tensile strength and elongation. The tensile strength is obtained by simply dividing the peak load observed during the test by the cross-sectional area of the sample.

Topics: ASTM Tests, Tensile Test, Foam

ASTM F88-94 Package Peel Tensile Strength is summarized below. This specification is focused on the force required to pull open a seam of a package. It is vital to protect the contents of a package, especially when the package contains sterilized medical instruments or a medical device. Conditions can effect the the type of package and the type of seal that could be used for a package design. The type description of a package seal being tested needs to be clearly defined. ADMET's PC Based, MTESTQuattro controller allows up to 10 user definable fields to describe the specimen. It is imperative when the evaluator compares different types of packaging seals, they know exactly how each is defined.

Topics: ASTM Tests, Biomedical, Tensile Test, Packaging, seal strength

Here is a short video of the test:

Topics: ASTM Tests, rubber, Plastic, Tensile Test