ASTM D412 ( D 412 ) covers the tensile properties of thermoset rubbers and thermoplastic elastomers. The specification describes two test methods, A and B. Method A is common and can be performed on a universal testing machine (tensile testing machine). If you are going to perform this test, you should read the entire specification from ASTM. This is a quick summary to decide if this test is right for you, and to point out what equipment you need to perform the test.

This video shows the basic steps necessary to perform the ASTM D412 test:

Test Procedure:

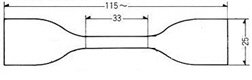

1. Cut or injection mold your material into a "dumbbell" shaped specimen.

2. Load the specimen into tensile grips.

3. Attach the optional extensometer to the sample

4. Begin the test by separating the tensile grips at a speed of 20 inches per minute

5. End the test after sample break (rupture)

Analysis obtained:

1. Stress at user-specified extension or elongation

2. Tensile Yield Stress

3. Tensile Yield Strain

4. Tensile Strength at Rupture

5. Elongation at Rupture

Equipment required:

1. Universal testing machine (tensile testing machine) with these minimum specifications:

A. Servo-controlled to keep a constant rate of speed during the test (+/- 2 inches/min)

B. At least 30 inches of crosshead travel or more for high elongation materials

C. Most small and common 1kN (225 pound) load capacity machines will work for the loads of the materials tested to this specification

All of our eXpert 2600 series dual column machines meet these requirements, and it is also common to use our single column eXpert 7601 XLT with 53 inches of crosshead travel.

2. An extensometer is optional but recommended. We recommend one for two reasons. First, dumbbell specimens do not have uniform widths which cause errors when both the wide and narrow sections of the dumbbell shaped specimen elongate at different rates. Secondly, elongation is usually an important design characteristic of rubbers and elastomers so an extensometer can be used to improve accuracy of the measurement.

3. Software or suitable electronics are required to operate the machine and to take the measurements. Basic systems will provide the raw data, and stress-strain charts. Using these sources of data, you can determine and calculate all of the analysis listed above. However, fully PC based systems have the capability to calculate all of these automatically. For example, our MTESTQuattro testing software has built in support for ASTM D412 and all of these calculations are provided immediately after performing the test.

4. Tensile grips hold your specimen during the test as it is being pulled apart. Quite often, hard specimens are difficult to hold properly as premature breakage and slippage can be common. However, rubbers and elastomers usually lend themselves to being easily held in a variety of grip designs such as manual vise grips, pneumatic grips, wedge grips, or eccentric roller designs. The most common and easy to use grips are manual vise or pneumatic grips with rubber coated or serrated insert faces.

Click here for a quote for our 1kN, 2.5kN, or 5kN eXpert 7600 machine equipped to perform the ASTM D412 test. Or click here if you need a larger dual column machine.

This is a new version of this earlier post.