The basic test procedure for determining the insertion and removal torque is as follows:

ASTM F543 Annex A2 Bone Screw Test on Vertical Torsion Tester.

Topics: ASTM Tests, Biomedical, Torsion, implants

ASTM F543- A1 Metallic Bone Screw test on 20Nm Torsion Tester

Annex A1 is used to measure torsional yield strength, maximum torque and angle at break for metallic bone screws. A description of the ASTM F543-A1 test procedure is as follows:

Topics: ASTM Tests, Biomedical, Torsion, implants

Testing System for ASTM F1717 Spinal Implant Biaxial Testing

Static Compression Bend Test - Load at a crosshead displacement rate not to exceed 25 mm/min and record the load vs displacement curve. Calculate displacement at 2% offset yield, elastic displacement, compressive bending yield load, compressive bending stiffness, compressive bending ultimate displacement and ultimate load.

Topics: ASTM Tests, Biomedical, implants, Biaxial, Fatigue

Annex A1- ASTM F382-A1 measures the bending stiffness, bending structural stiffness, and bending strength from a single cycle bend test on a metallic bone plate.

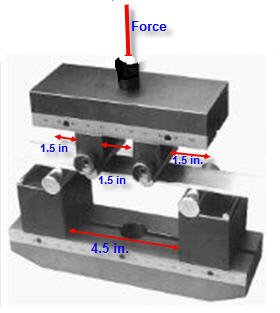

Annex A1 is used to determine values for the mechanical response of bone plates to specific bending loads and provides some insight into the mechanical response of the subject bone plate. The bone plate is positioned on a 4 point bend fixture (shown below) installed in an Universal Testing Machine (UTM). The bend fixture should use cylindrical rollers with diameters between 6-12 mm. The recommended test configuration locates the loading rollers at one third points. The spacing of the rollers, however, is dependent on the location of the screw holes in the bone plate. Apply bending moments of increasing magnitude via crosshead position rate control. Generate a load versus load point displacement graph. Determine the bending stiffness, bending structural stiffness and bending strength.

Topics: ASTM Tests, Biomedical, Bend Testing, implants

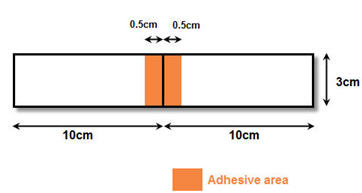

Materials that adhere living tissues together are being used more frequently in surgical procedures as adjuncts to sutures or as replacements. ASTM F2458 - 05 is a standard test method for determining the comparative wound closure strength of tissue adhesives. With the appropriate substrate, F2458 can also be used in quality control testing of tissue adhesives. This test method can be used to compare adhesives for chance of fatigue, type of failure, and environmental changes.

Topics: ASTM Tests, Biomedical, Adhesive, Tissue

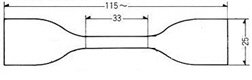

ASTM D412 Tensile Strength Properties of Rubber and Elastomers

Topics: ASTM Tests, Biomedical, rubber, Plastic, Tensile Test, Packaging, Extensometer

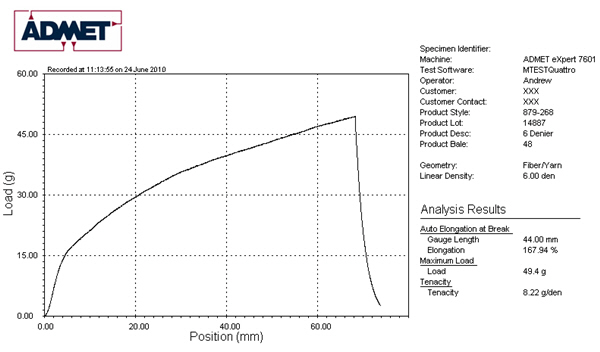

To determine the breaking strength, elongation, etc. of threads, yarns, or other single strand textiles, ASTM D2256 (D 2256) is by far the most common specification that is followed. This is a relatively simple tensile test whereby thread is pulled at a constant rate of speed until it breaks. Please see the video below that shows how the test is performed:

Topics: ASTM Tests, Textile, Tensile Test

ASTM D882 Tensile Strength Properties of Thin Plastic Film

One of the most common specifications that our customers follow is ASTM D882 which is the Standard Test Method for Tensile Properties of Thin Plastic Sheeting. This test is very similar to the common ASTM D638 test whereby plastic material is pulled until in breaks in order to measure elongation, tensile modulus, tensile yield strength, and tensile strength at break. However, it is designed specifically for thin sheeting and film less than 1 mm (0.04") thick.

Topics: ASTM Tests, Plastic, Tensile Test, Packaging, Film