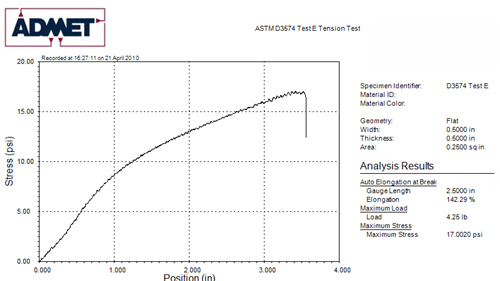

The purpose of performing the tension test on polyurethane foam is to measure the tensile strength and elongation. The tensile strength is obtained by simply dividing the peak load observed during the test by the cross-sectional area of the sample.

The foam tensile strength test is similar to testing other polymers, but gripping and measuring extension require a bit more care. The minimum foam thickness during testing is 12.5mm and it is common to measure thicker samples. Foams do not typically have high tensile strengths, so low force (1kN) capacity grips are fine. Therefore the best grips to use are wide opening (at least 20mm) 1kN capacity vise or pneumatic grips.

Measuring extension is tricky. Because the sample is "dogbone" shaped, using grip separation to measure elongation is less than ideal due to the error caused by the non-uniform specimen width. Despite this, it is still common to measure elongation using grip separation. The reason for this is because contact extensometers clip on the foam and this distorts the sample thickness and causes premature sample breakage. Non contact optical extensometers work well but the high cost (often times more expensive than the rest of the testing machine) makes them unpractical.

With the right equipment, the test is actually quite easy. A video of a foam tensile strength test is shown here:

We have a lot of information on polyurethane foam testing according to ASTM D3574. Click the links below to learn more:

1. General Equipment requirements for ASTM D3574

2. Indentation Force Deflection Test (IFD)

3. Tear Strength

Click here if you would like to ask an engineer a question, or click here if you would like a quote on a system.

Notice how the extensometer distorts the foam too much

Foam "dogbone" shape specimen

Tensile test setup

Test report from MTESTQuattro software