Accurate mechanical testing requires not only familiarity with measurement systems, but also some understanding of the planning, execution, and evaluation of experiments. Much experimental equipment is often “homemade,” especially in smaller companies where the high cost of specialized instruments cannot always be justified. If the designer of the “homemade” equipment does not carefully consider how the design functions under test conditions, then the stress vs. strain diagram may be in error.

What Makes an Accurate Universal Testing Machine?

Topics: universal testing machine, Product Information, Testing Tips

The terms below are commonly referenced in the world of materials testing. Many of these definitions are taken from ASTM E6 Standard Terminology Relating to Methods of Mechanical Testing.

Topics: News, universal testing machine, Testing Tips

Mechanical Property Testing doesn't need to be expensive or difficult

Whether you are in medical device production or R&D testing, mechanical property testing is a critical step in ensuring the quality of your product. Unfortunately, the testing process can be expensive and time consuming. Some companies hire specialized engineers to maintain large and expensive pieces of testing equipment, others decide to outsource their testing needs to laboratories that may or may not understand the needs of your customers. At ADMET, we decided to make mechanical testing easy and affordable.

Topics: Biomedical, Bend Testing, Bone screws and plates

Flexural Bend Testing Machine for Large Plastic Samples ASTM D790

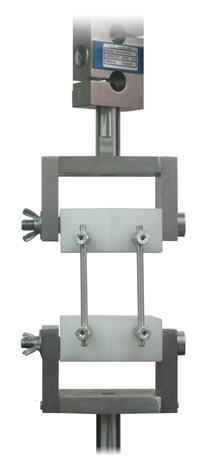

Recently, a city government's engineering department approached us with a need to test large plastic sewer pipe liners for flexural modulus and strength according to ASTM D790. Our normal recommendation would be a dual column eXpert 2600 universal testing machine with our MTESTQuattro software as this would provide the necessary force, size, and software to be able to run the test properly and calculate the modulus automatically. However, the customer had a limited budget which made our original recommendation not affordable. We were tasked with configuring a system that met their budget without sacrificing any accuracy in the test data. Our first idea was to use our eP2 touchpanel controller rather than MTESTQuattro software. While our MTESTQuattro software automatically calculates flexural modulus, our eP2 digital controller does not. The eP2 allows you to export the test data to your computer which can then be opened in Microsoft Excel or a similar program. This worked because our customer was willing to calculate modulus using the exported data. The second idea was to use our 5kN single column eXpert 5603 instead of the dual column eXpert 2600. However, single column machine designs have tolerances that can adversely affect the data used to calculate flexural modulus. These tolerances are column flexure, screw backlash, load cell deflection, etc. Therefore, we added a displacemnt transducer in place of crosshead position which makes the tolerances of the machine irrelevant. The transducer mounts directly to the flex fixture base and directly reads the top loading nose. This provides an extremely accurate displacment reading. To add greater stability to the system, we used a "pancake" style fatigue rated load cell in place of a normal "S" shaped load cell. The final configuration of the machine ended up being our most accurate and least expensive testing system we have developed for testing large samples according to ASTM D790. This is what the machine looked like:

Topics: ASTM Tests, Plastic, universal testing machine, Bend Testing

ADMET to exhibit at NASS Annual Meeting October 2010

Orlando, FL- October 5, 2010 – ADMET, Inc., a provider of integrated materials testing systems, is showcasing their line of single, dual, and biaxial testing systems at the North American Spine Society’s 25th Annual Meeting. Booth #1891 The testing systems that will be featured are commonly used for testing biomedical materials and medical devices that require both static and dynamic testing profiles as well as uniaxial, biaxial, and long term fatigue.

Topics: Announcements, Biomedical, implants

Planar Biaxial Testing System for Biological Tissue

Constitutive models are necessary to predict the mechanical behavior of biological tissues. However, biological materials present challenges in constitutive modeling due to their complex mechanical behavior. Their oriented fibrous structures often exhibit pronounced mechanical anisotropy. Due to anisotropy, stress strain data generated from uniaxial tests cannot be used to extrapolate to generalized three-dimensional constitutive equations. Since biological tissues are generally considered incompressible, planar biaxial testing allows for a two-dimensional stress-state that can be used to characterize their mechanical properties and validate the constitutive models.

Topics: Biomedical, Textile, Biaxial, Tissue

UMASS Lowell- Plastics in Medical Device Conference- ADMET a sponsor

ADMET was one of the sponsors of Plastics in Medical Devices held at UMASS Lowell Inn and Conference Center in Lowell, MA on Tuesday, April 20, 2010. The conference was co-organized by the SPE Medical Plastics Division, the ENE SPE Section and the UML Plastics Engineering Department.

Topics: Announcements, Biomedical, Plastic

Automatic Concrete Cylinder Tester for ASTM C39 Strength Reports

Speed Control

Concrete exhibits loading-rate sensitivity relative to compressive strength,1,2 so ASTM C39, "Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens,"3 limits loading rate to 0.2 to 0.3MPa/sec (28 to 42 psi/sec). This helps ensure consistency within and among laboratories.

Topics: Concrete Testing, Compression Test

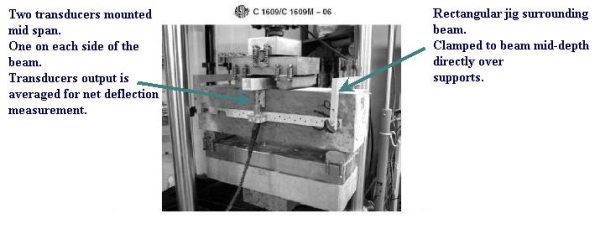

ASTM C1609 Flexural Testing of Fiber-Reinforced Concrete Beams

Fiber reinforced concrete (FRC) is finding increased use in construction. FRC offers several advantages over rebar or wire mesh reinforced concrete including increased crack resistance, ductility, energy absorption, impact resistance and residual strength. FRC can also significantly lower materials and labor costs compared to rebar or wire mesh reinforced concrete.

Topics: Concrete Testing, Compression Test, Bend Testing, Servo-Automatic Control

Torsion Testing Conical Luer Fittings and Connectors for Medical Devices

Topics: Biomedical, Torsion, Product Information, delivery device