For 20 years ADMET's focus has been on producing leading edge mechanical testing systems that are reliable, exceed ASTM/ISO accuracy requirements, and are easy to learn and use. During this time we have remained steadfast to two founding principles; a willingness to tailor our systems to meet your needs; and to provide efficient and responsive customer service; thus giving you the confidence to test with certainty.

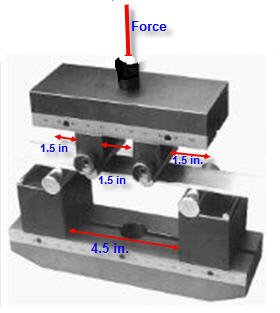

ASTM F382-99 Metallic Bone Plate Material 4 point Bend Test

Annex A1- ASTM F382-A1 measures the bending stiffness, bending structural stiffness, and bending strength from a single cycle bend test on a metallic bone plate.

Topics: ASTM Tests, Biomedical, Bend Testing, implants

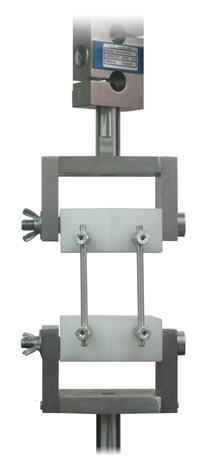

ASTM F1717 Spinal Implant Construct Biaxial Testing

Spinal Implants are tested according to several ASTM standards. ASTM F1717 is intended to provide a basis for the mechanical comparison among past, present and future spinal implant assemblies. Three static and one fatigue mechanical test of a spinal construct are governed by ASTM F1717. The three static tests are compression bending, tension bending and torsion. The fatigue test is a compression bending test. The mechanical tests are conducted using simplified loading schemes and do not attempt to mimic the complex loads of the spine. An outline of the four test procedures is as follows:

Topics: ASTM Tests, Biomedical, implants, Biaxial, Fatigue

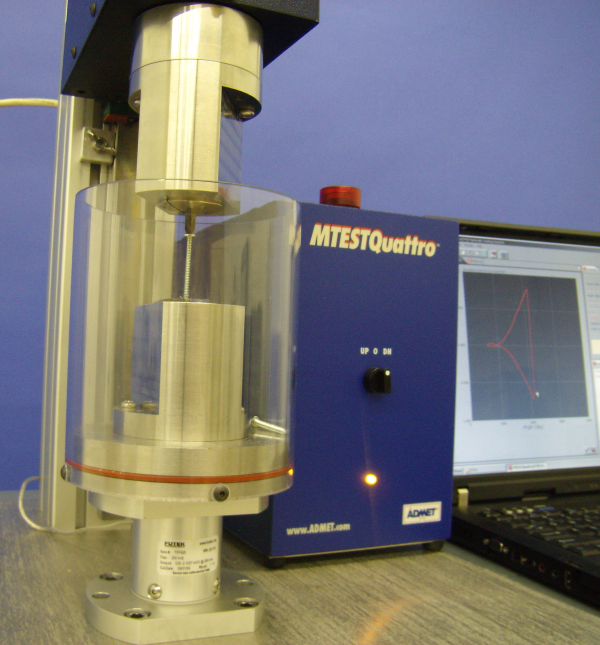

UNCC receives ADMET Torsion Tester for Bioactive Bone Screws

The Orthopedic Tissue Engineering and Materials Lab at the University of North Carolina Charlotte (UNCC) was the winner of ADMET, Inc's 20 year anniversary celebration biomedical testing system giveaway. Drs. Ahmed El-Ghannam and Nigel Zheng at UNCC head a research team involved with the use of bioactive ceramic and bioactive ceramic-polymer composites as orthopedic fixation devices. To fulfill their testing needs, ADMET has awarded the team an eXpert 81T 20 Nm (177 in-lb) Vertical Torsion Testing System equipped with the PC based MTESTQuattro® Materials Testing System and an immersion bath.

Topics: ASTM Tests, Biomedical, Torsion, implants

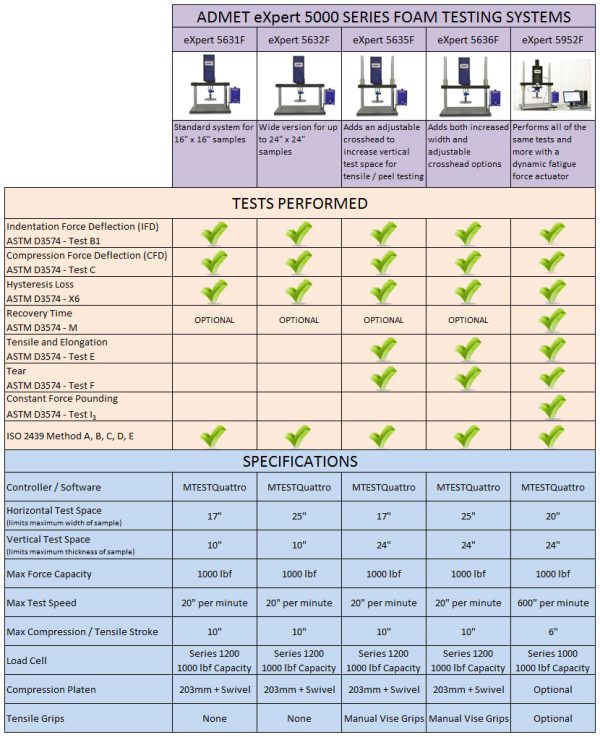

Testing Equipment Required for ASTM D3574 Urethane Foam

ASTM D3574 (D 3574) applies to slab, bonded, and molded flexible cellular urethane foams. There are many tests in this specification including tests for density, ball rebound, airflow, etc. ADMET manufacturers systems that perform the following common mechanical tests in the specification:

Topics: Compression Test, ASTM Tests, Foam

Annex A1 is used to measure torsional yield strength, maximum torque and angle at break for metallic bone screws. A description of the ASTM F543-A1 test procedure is as follows:

Topics: ASTM Tests, Biomedical, Torsion

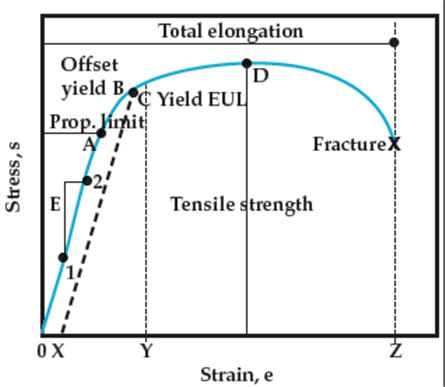

Determining Tensile Test Offset Yield Strengths using Extensometer

Typical points of interest when tensile testing a material include:

ultimate tensile strength or peak stress; modulus of elasticity, offset yield strength, which represents a point just beyond the onset of permanent deformation; and elongation at break.

Topics: Troubleshooting, Testing Tips

ADMET awards Medical Adhesive Testing System to MIT/Harvard Lab

Topics: News, Biomedical, Adhesive

ASTM D 882 Tensile Strength Properties of Thin Plastic Film

Topics: ASTM Tests, Plastic, Tensile Test, Film

ASTM F543 Annex A2 is used to measure the torque required to drive a bone screw into a test block made of a rigid unicellular polyurethane foam. The results obtained from this test bear no direct correlation to the torque required to insert a bone screw in human or animal bone. This method is used as a quality control check for maintaining product uniformity.

Topics: ASTM Tests, Biomedical, Torsion, implants