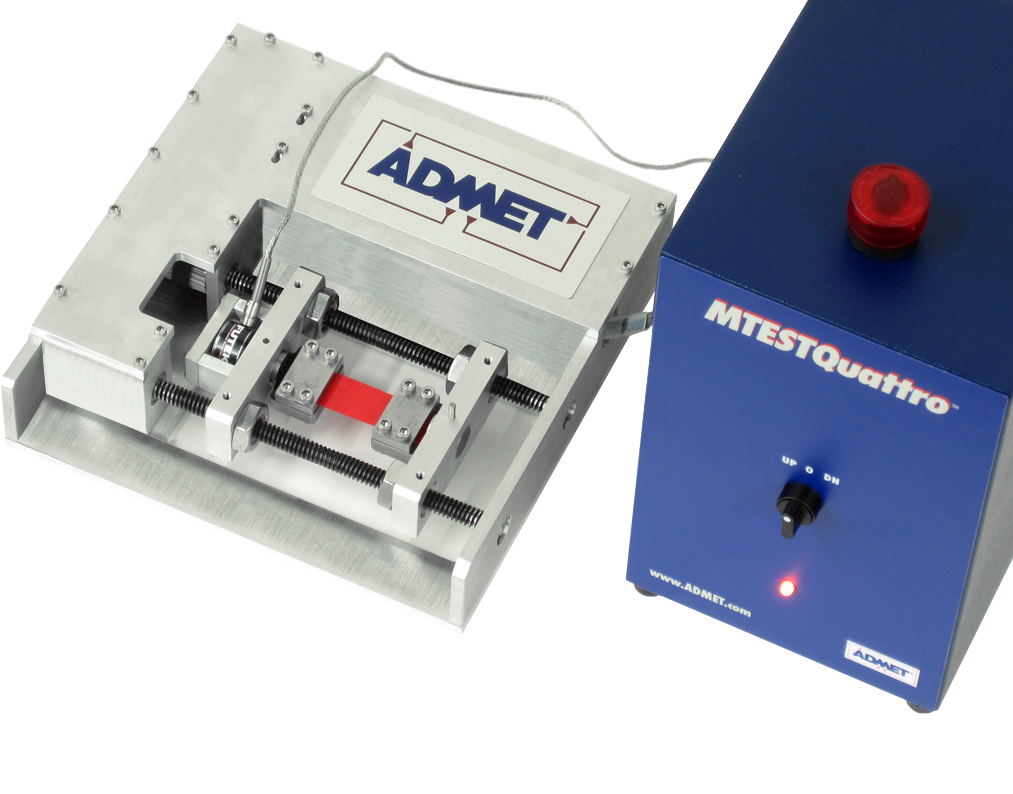

There are several ASTM and ISO specifications that require Torque Testing;ISO 594-1, ASTM F543, ASTM 2502, F1541, and A938. There are also many medical device companies that could use a torsion testing system for R&D and prototyping. Many times, the axial forces are low, and the torque capacity is less than 50Nm. ADMET's 81T Torsion Tester comes in 1-100Nm capacity with dead weight pulley system to offset or to apply load to the sample. A Biaxial configuration, for both linear and torsional control, is available in single or dual column configurations at an additional cost.

Table Top Torque Testing Made Simple - Medical Device Testing

Topics: Biomedical, Torsion, implants, Biaxial

Contract manufacturers can offer testing services to increase revenue

Is the thought of test equipment being too expensive or too hard to operate, holding you back from offering this service to your customers?

When asked, will you perform the mechanical property testing of a prototype or finished product, do you refer to a 3rd party test lab? You could be generating revenue by offering testing. Many times a simple tensile test, compression test, or torsion test is all that is needed.

How to set up your business to get ready for testing.

- Buy a Testing System at a reasonable cost, that is low maintenance, that is easy to use, and that you can use for a variety of testing applications.

- Work with a manufacturer that is willing to tailor the system to meet your varied testing needs.

- Determine what type of testing your customers will appreciate most.

- Learn about common ASTM/ISO standards to help guide your test profile set up.

Using the ADMET Test System and MTESTQuattro controller, this is how easy it is to set up a test;

- In MTESTQuattro, you use the servo control tab to set up your testing profile.

- You can set up a ramp, saw tooth, or sinusoid profile. 1 cycle or 1 million cycles follow the same easy to distinguish fill in menu set up. Start up training is free.

Types of tests commonly performed on our single or dual column systems using MTESTQuattro or MTESTQuattro Torsion or MTESTQuattro Biaxial.

- Static-Pull, Compress, or Twist to Break -failure test.

- Static-Pull, Compress, or Twist to an end limit of load or position.

- Fatigue-Pull, Compress, or Twist in motion for a predetermined number of cycles unless failure occurs.

What would you like to do with the data after the test?

Customers will want to see a test report. The ADMET report contains; descriptive information about the sample, the test profile, your own comments pre or post test, an xy plot. You can choose a wide range of common analyses that will be auto-calculated post test in MTESTQuattro products. (Load/Extension/Position Analyses--Maximum/Minimum Analyses--Yield Analyses--Modulus/Strain Ratio Analyses--Elongation Analyses--Specification Analyses.)

- ADMET offers simple graphing solutions;

- Plot Load, Position, Stress, or Time for uniaxial tests

- Plot Torque, Angle or Time for torsion tests

- Plot Load(1 or 2), Position(1 or 2), Torque(if relevant), Angle(if relevant), Stress, Time for biaxial

- Color Multi Plot group of test samples or variety of sample test data.

- Cursor to highlight specific points, rescale, and highlight specific areas of test data.

- Output in .jpg, bitmap,.csv, and other formats.

What about statistics?

Statistical Summary automatically generated from test data gathered in a test results file.

What more? ADMET configures testing systems to meet the varied demands of contract manufacturers testing needs. Our systems are used for very simple and very sophisticated testing applications. Our MTESTQuattro controller is versatile and will perform sophisticated profiles requiring extensometers, off-center loading, and fatigue set up. This can be accomplished on the ADMET Test Systems without having to purchase additional software modules. All of our testing systems and controllers are manufactured in the USA.

Topics: Biomedical, universal testing machine, Product Information, Testing Tips

UMASS Medical School -Validate Device for Hip Fracture Healing with ADMET Testing System

Topics: MTESTQuattro, Biomedical, eXpert 2600, metal, implants

Materials testing is often the last step in the manufacturing process. Yet, quality is the result of both the process and the material. If the material that goes into the product is defective, then the product may be defective. Quality cannot be put in after the fact. In forming materials, understanding the material’s properties can help to better predict the manufacturing outcome.

Topics: News, universal testing machine, Product Information, Testing Tips

Strength refers to the ability of a structure to resist loads without failure because of excessive stress or deformation. Typical points of interest when testing a material include: ultimate tensile strength (UTS) or peak stress offset yield strength (OYS) which represents a point just beyond the onset of permanent deformation; and the rupture (R) or fracture point where the specimen separates into pieces.

Topics: News, Compression Test, universal testing machine, Tensile Test, Adhesive, Product Information, Testing Tips

Make Sure to Calibrate Your Universal Testing Machine Annually

ASTM requires that load and strain measuring devices be calibrated annually. If any device has been damaged or is subjected to excessive use, more frequent calibrations should be done. Calibration records should be kept to determine when it’s time to replace or refurbish a device. Each device has its own certified range and, therefore, no results should be reported outside the certified ranges.

Topics: News, universal testing machine, Product Information, Testing Tips

Mechanical Testing of Nanocomposites and Tiny Devices

Nanocomposites are typically polymer-based materials in which the microstructure and mechanical behavior are tailored via the incorporation of additives or nanometer-sized particles. They have significantly enhanced mechanical performance, as well as other properties such as electrical conductivity, thermal conductivity, and resistance to permeability and abrasion.

Topics: News, Biomedical, universal testing machine, Product Information, Testing Tips

Upgrade/Retrofit or Replace your Old Universal Testing Machine?

So what to do when an old system breaks or your customer requires a test that cannot be performed with your existing machine? Do you replace the machine with a new one or do you upgrade/retrofit the existing machine?

Topics: News, universal testing machine, Product Information, Testing Tips

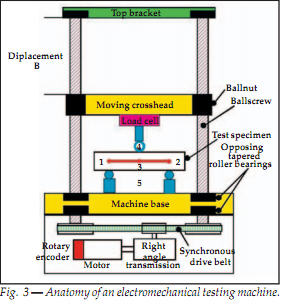

There are many types of testing machines. The most common are universal testing machines, which test materials in tension, compression or bending. The primary use of the testing machine is to create the stress-strain diagram. Once the diagram is generated, a pencil and straight edge or computer algorithm can be used to calculate yield strength, Young’s Modulus, tensile strength or total elongation.

Topics: News, universal testing machine, Testing Tips

Factors that Affect Mechanical Property Measurement - Load cell Accuracy

Mechanical Testing is that part of engineering design, development, and research that provides data about material properties. Testing is also required during manufacturing to ensure that a material or product meets some predefined specification. Critical to the process is the accuracy of the load cell used to take the load measurements.

Topics: News, universal testing machine, Testing Tips