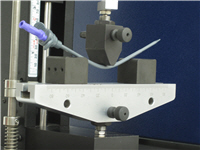

Bend testing (also flex or flexural testing) is commonly performed to measure the flexural strength and modulus of all types of materials and products. This test is performed on a universal testing machine (tensile testing machine or tensile tester) with a 3 point or 4 point bend fixture. Most common for product testing is the 3 point test.

How to Perform a 3 Point Bend Test on a Universal Testing Machine

Topics: Plastic, Bend Testing

How to Perform an ASTM D638 Plastic Tensile Strength Test

Topics: ASTM Tests, Plastic, Tensile Test, Extensometer

Outdoor Gear Buckle and Webbing Breaking Strength Tensile Test

This is a test of a side release buckle used to connect a lashing strap. As you can see in the video, this buckle would be fine for lashing a sleeping pad on a backpack, but you certainly would not want to use it for climbing.

Topics: Compression Test, Tensile Test, Packaging, Bend Testing

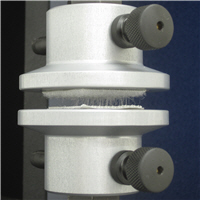

Hook and loop fastener strength test on a universal testing machine

Hook and loop (often times referred to by the trade name Velcro) fasteners are commonly tested through both a Peel Strength "T" Method (ASTM D5170) and Shear Strength Dynamic Method (ASTM D5169). Hook and loop fasteners are also used in applications where separation occurs purely in the tension direction. This video shows a test where an adhesive backed hook and loop fastener is adhered to a pair of compression platens mounted to a universal testing machine (tensile testing machine). The test has been designed so that in one test the hook and loop is loaded to 1 pound of force and then retracted to measure the bonding strength. It then continues to load to 10 pounds of force, then retract, then load to 20 pounds, then retract, and so on until 80 pounds of force. After the test is completed, the strength can be measured by analyzing the test report with load on the "Y" axis and time on the "X" axis.

Topics: ASTM Tests, Plastic, Tensile Test, Adhesive, Packaging

How to Perform an ASTM C469 Concrete Compression Test

Topics: Concrete Testing, Compression Test, ASTM Tests

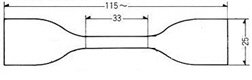

How to Perform an ASTM D412 Rubber Elastomer Tensile Strength Test

ASTM D412 ( D 412 ) covers the tensile properties of thermoset rubbers and thermoplastic elastomers. The specification describes two test methods, A and B. Method A is common and can be performed on a universal testing machine (tensile testing machine). If you are going to perform this test, you should read the entire specification from ASTM. This is a quick summary to decide if this test is right for you, and to point out what equipment you need to perform the test.

Topics: ASTM Tests, rubber, Plastic, Tensile Test, Extensometer

90 Degree Adhesive Peel Strength Test on a Universal Testing Machine

This video shows a 90 degree adhesive peel strength test on an ADMET eXpert 7601 universal testing machine (tensile testing machine). We fit the eXpert 7601 with our 90 degree peel strength fixture and one vise grip on the top crosshead to hold the free end of the tape. The fixture has numerous tapped holes that allow you to clamp a multitude of various parts and substrates to the test bed. This test measures the maximum load and also the average load of adhesive tape bonded to a Polystyrene foam substrate. The average was taken after 1" of displacement and continued through 6" of displacement. Usually, the highest force is observed at the beginning of a peel test and then it levels out throughout the remainder of the test. Starting the average force calculation after 1" removed the "starting force" from the average calculation.

Rubber Seal Compression Testing to Obtain Load vs. Deflection Curve

Topics: Compression Test, rubber

Torsion Fatigue Tester for Medical Device Testing

ADMET offers electromechanical and servo-hydraulic fatigue testing systems for tension, compression, torsion and biaxial testing applications. All systems are engineered to meet your needs (The eXpert 81T 30Nm Torsion Fatigue Tester shown in the video is for medical device testing.).

Topics: Biomedical, Torsion, Fatigue

Topics: Biomedical, Tensile Test, Tissue