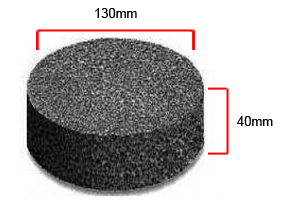

Similar to ASTM D1621 and ISO 884, ISO 3386/1 is a testing standard designed to measure the compression stress/strain (load divided by specimen surface area at a certain compression percentage) characteristic of cellular flexible polymeric material (i.e. foam). This is a general guide designed to help you understand the basic test procedure and equipment needed to test your products and materials to this standard. When you are ready to perform this test, please refer to and follow the exact specifications in the official ISO 3386 document.

ISO 3386 Compression Stress of Foam How to Guide [video]

Topics: Compression Test, ASTM Tests, Foam

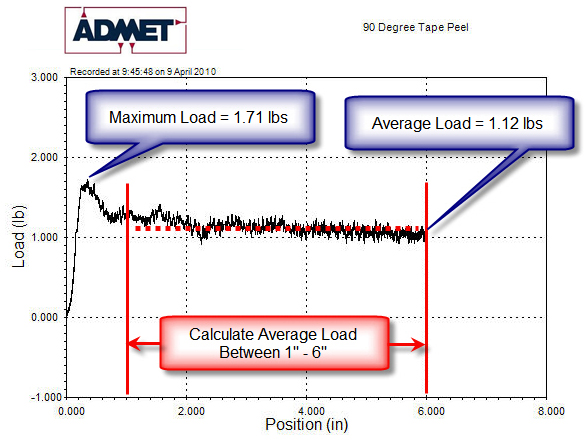

ASTM D903 Peel or Stripping Strength of Adhesive Bonds How to Guide

ASTM D903 is one of the most commonly performed adhesive strength tests. An adhesive is bonded to a material and peeled back at 180 degree angle to measure average peel strength. This post is intended to help you understand the basic test procedure and the equipment needed to perform this test with certainty. When you are ready to test your adhesives to this standard, please refer to and follow the steps in the official ASTM D903 specification.

Topics: ASTM Tests, Adhesive

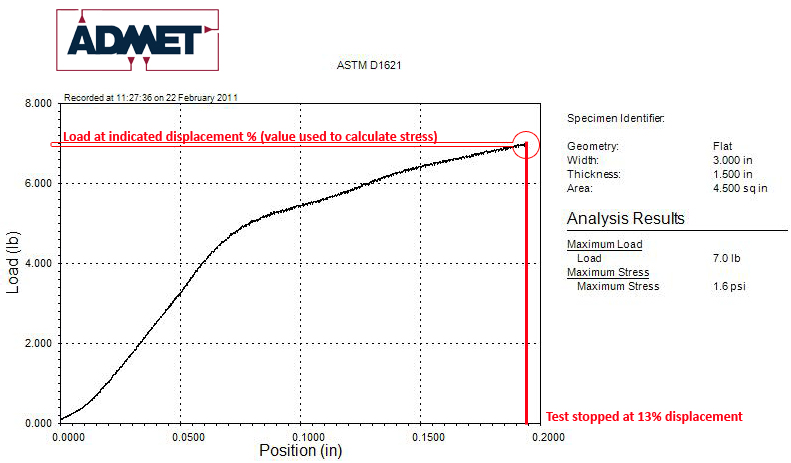

ASTM D1621 Compressive Properties of Rigid Cellular Plastics How to Guide

Similar to ISO 844, ASTM D1621 is a testing standard designed to measure the compressive properties of rigid cellular plastics (i.e. foam). This post is intended to help you understand the basic test procedure and the equipment needed to perform this test with certainty. When you are ready to test your materials to this standard, please refer to the official ASTM D1621 specification.

Topics: Compression Test, ASTM Tests, Foam

ASTM D5458 Peel Cling of Stretch Wrap Film How to Guide

Stretch wrap film, commonly made from polyethylene plastic, is a clear packaging film normally used to wrap large or bulk items for transportation or warehousing purposes. ASTM D5458 is a testing standard designed to measure the “cling” between two layers of stretch wrap film. This is a relevant measurement because two or more layers of stretch wrap are usually in contact with each other. For example, stretch wrapped pallets require several layers of film to secure and are usually moved across, or transported on top of, other wrapped pallets. This post is designed to help you understand the test procedure and equipment needed to perform this test with certainty. When you are ready to test products to this standard, please refer to and follow the steps in the official ASTM specification.

Topics: ASTM Tests, Plastics, Adhesive, Packaging, Film

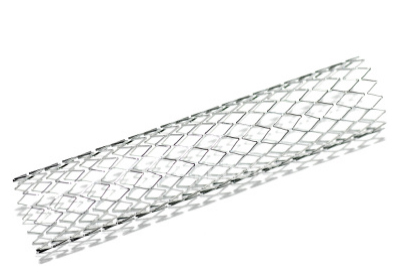

ASTM F2516 Tension Testing of Nitinol How to Guide

Nitinol is a metal alloy composed of titanium and nickel. nitinol is characterized by its biocompatibility, elasticity, fatigue strength, and ability to return to its original shape after deformation (shape memory). Although nitinol is used in industries ranging from robotics to clothing, it is in the medical field where the material really shines. Medical applications of nitinol include: vascular stents, eyeglasses, orthodontics, prosthetics, surgical applications, and much more.

Topics: Metals, ASTM Tests, Biomedical, Tensile Test, implants

3 and 4 Point Bend Testing of Semiconductor Devices

Several factors are driving manufacturers to try and reduce the size, and more importantly thickness, of semiconductors devices used to make microchips. As consumers push for gadgets that are smaller, lighter, yet more powerful, engineers must find ways to reduce the size and weight of the circuit boards and processors used to power them. In addition, an overall increase in demand for electronics has decreased the available supply of silicon wafers used in the fabrication of internal electronic components. Developing devices that use less semiconductor material and identifying the best edge cutting and surface treatment methods for these components could decrease material use and manufacturing errors.

Topics: Plastics, Bend Testing

ASTM D3330 Peel Adhesion of Pressure Sensitive Tape How to Guide [video]

Topics: ASTM Tests, Biomedical, Adhesive, Packaging, Film, Testing Tips

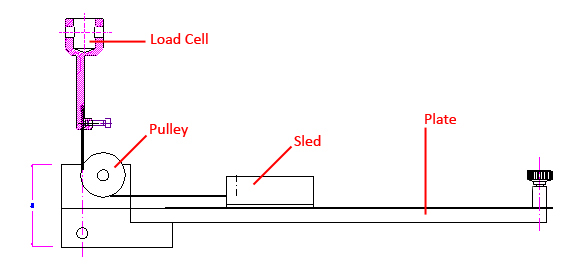

ASTM D1894 Coefficient of Friction Test on Plastic How to Guide

ASTM D1894 is a testing standard designed to measure the friction of plastic film and sheeting. This post should help you understand the basics of the test procedure and help you choose the right equipment to perform this test accurately. For complete instructions and before testing your products to ASTM D1894, please refer to the official specification.

Topics: ASTM Tests, Plastic, Friction, Testing Tips

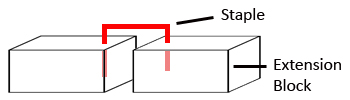

ASTM F564 details three types of tests commonly conducted during the product development process of metallic staples to be used in medical applications related to bone. This post is intended to help you understand the basic procedures and the equipment needed to complete the fatigue, pull-out strength, fixation strength, and bending tests explained in the specification. For complete instructions, please refer to ASTM F564.

Topics: ASTM Tests, Biomedical, Tensile Test, Bend Testing, implants, Fatigue

ASTM D2412 Load Deflection of Plastic Pipe Test How to Guide

Topics: Compression Test, ASTM Tests, Plastic