Dental materials ranging from composite resin fillings, to porcelain to metal crowns and bridges, to alginate impression material, to dental adhesives for bonding and restorative dentistry are all tested for their mechanical property strengths. ISO 6872, ISO11405, ISO14801, ISO 9917, and other standards specify the requirements and the corresponding test methods to access dental materials.

Dental Adhesive, Composite Resin, and Ceramic Material Tensile, Shear, and Flexural Testing System

Topics: ASTM Tests, Tensile Test, Flexural testing, Dental

10 Tips to Help You Choose the Perfect Universal Testing System

Choosing the right testing machine can help lower costs and accelerate product development. Whether company is buying its first testing system or is looking for a different type of system to perform tests on a new product, purchasing a testing system is an important decision. We’ve put together 10 easy steps to help you select the perfect system for your testing application.

Topics: Testing Tips

ASTM D412 Tensile Strength Properties of Rubber and Elastomers

ASTM D412 (D 412) is the most widely referenced testing standard for measuring the tensile properties of thermoset rubbers and thermoplastic elastomers. ASTM D412 covers two test methods, A and B. The more popular method is A, which can be performed using a universal testing machine also known as a tensile testing machine or tensile tester. This is a general guide intended to help you understand the basic test procedure and the different system configurations you can use to perform this test. When you are ready to test your products or materials to this standard, we recommend purchasing and referencing the official ASTM D412 document.

Topics: ASTM Tests, Plastic, Tensile Test

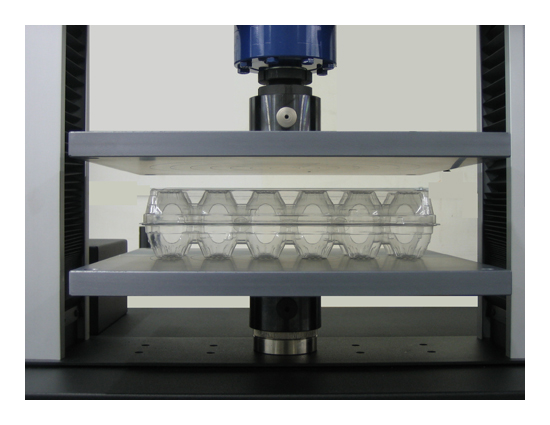

ASTM D642 Test Method for Determining Compressive Resistance of Shipping Containers How to Guide [video]

ASTM D642 is a testing standard designed to measure the compressive strength or resistance of shipping containers and parts. During distribution and warehousing, items are placed under various compressive loads while being stacked and moved. Packaging components such as boxes, crates, and cases are designed to protect products while they are transported and stored. Testing packing components for compressive strength is needed to help guarantee the protection of the products inside them. ASTM D642 can be used to test packaging diagonally (along opposite edges) or top to bottom. This is a general guide designed to help you understand the basic test procedure and equipment needed to test your products and materials to this standard. When you are ready to perform this test, please refer to and follow the exact specifications in the official ASTM D642 document.

Topics: Compression Test, ASTM Tests, Plastic, Packaging

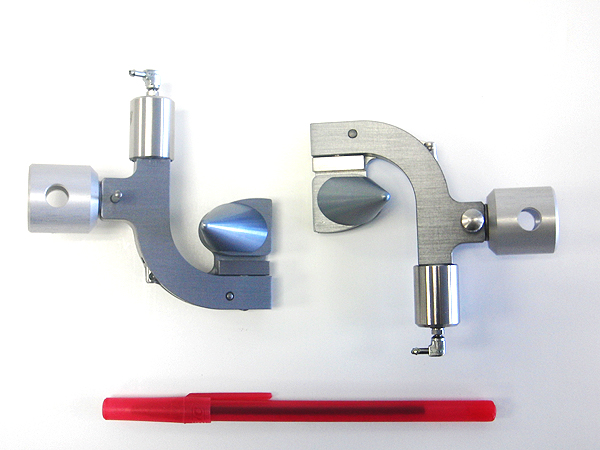

Fixture for Micro Tensile Testing of Thread [video]

When performing tensile tests on rope or thread, special fixtures are required. These fixtures, available in manual or pneumatic configurations, allow you to quickly load, properly align, and securely hold each specimen. Rope fixtures come in different sizes and load capacities, the size and strength of your specimen should determine which type of rope fixture you need.

Topics: Biomedical, Textile, Tensile Test

ASTM F2634 Polyethylene Butt Fusion Joint Test Testing Equipment

Test method ASTM F2634 is used to determine the quality of polyethylene (PE) butt fusion joints. This test is desinged for pipes with a diameter greater than 2.37" and a wall thickness greater than 0.25".

Topics: ASTM Tests, Tensile Test, Plastics

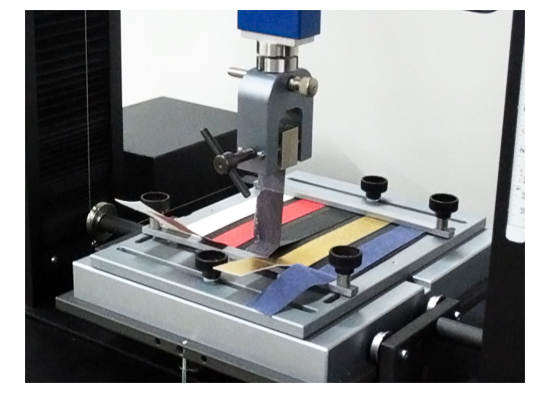

Quickly Perform 90 Degree Peel Tests on Multiple Specimens [video]

Virtually every ASTM and ISO adhesive testing standard, including ASTM D903 and ASTM D3330, requires that each test be repeated on at least 5 specimens. Peel testing procedures usually consist of attaching each specimen to a substrate, loading the prepared specimen onto a testing machine, running the test, removing the specimen, and repeating this process 5 – 10 times. Not only does this extend the time needed to complete a test, it can increase the chance of errors due to inconsistencies in substrates and loading position.

Topics: Adhesive

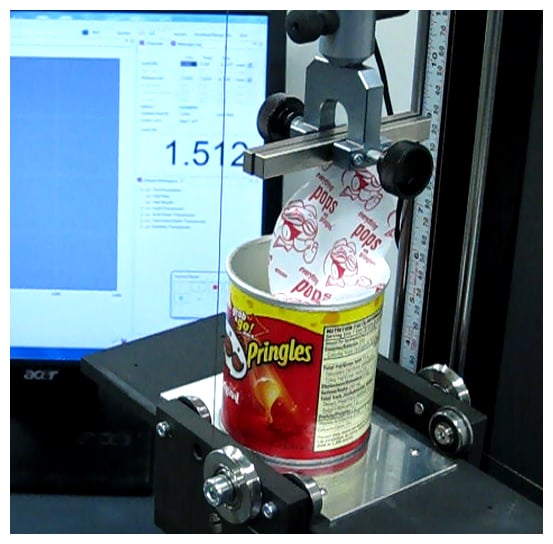

Peel tests are often used in packaging applications to determine the bond strength of freshness seals commonly found in food and medical packaging. We performed a 90 degree peel test to determine the force required to peel the freshness seal from a can of Pringles Potato Crisps.

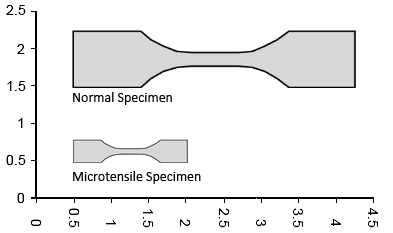

Most plastic tensile property tests, including tensile strength, elongation (at yield or break), and modulus of elasticity are performed on “dogbone” shaped specimens measuring 3 or more inches in length and .25 inches or more in width. In some cases, the application or availability of a material will require that a Microtensile specimen be tested. Microtensile are usually no more than 1.5 inches in length and .25 inches in width.

Topics: ASTM Tests, Plastic, Tensile Test, Film

From orthodontic bonding agents to wound closures, to gels for medical sensor pads, the term medical adhesive can refer to any product that is used to adhere or bond in a medical application. Medical adhesives can be categorized by application and adhesion method. Common applications include bandages, dental appliances, dental composites, wound closure, tissue repair, securing bone pins/screws, prosthetic assemblies and attachments, implants joints and connectors, medicinal patches, and medical sensor pads. The adhesion method refers to the way in which the adhesive is applied and the bond is activated. For example, pressure sensitive tapes (e.g. bandages) are bonded to the skin by applying pressure. Other medical adhesives, such as those used in dental applications, are activated by heat or UV light.

Topics: Biomedical, Adhesive

1.jpg)