I’ve had a few car breakdowns in my life that have left me stranded on the highway. Whenever this happens, I envy the lucky people who manage to live life without the need to own or drive an automobile on a daily basis. The trouble is that there is no way I can do all that I want to do in the time I have available without having my own car. Besides, my hatred of my vehicle quickly passes when I think about how reliable my car actually is. When you think about that there are roughly 30,000 individual parts in a modern automobile and with all the abuses we subject all these parts to – potholes, temperature extremes, lack of maintenance – it’s truly amazing that problems arise as seldom as they do. That’s because an incredible amount of R&D effort and testing goes into making sure all of these parts are properly engineered into the system.

Testing Automotive Interior Materials with a Universal Testing System

Topics: Textile, rubber, Plastic, universal testing machine, automotive

BioTense Bioreactor used in Northeastern University Cornea Research

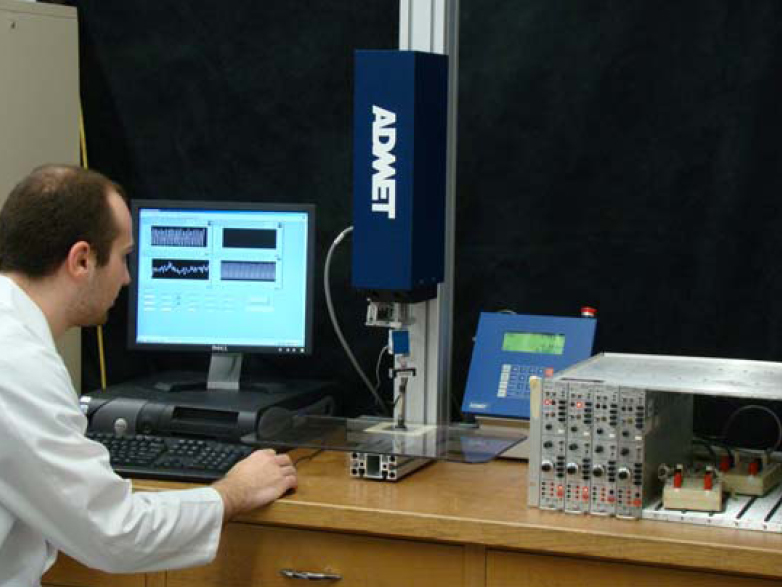

Northeastern University engineering professor Jeffrey Ruberti and his research colleagues are breaking new ground in the technique known as "hybrid tissue engineering" by attempting to control the behavior of human cells such that they can be induced to produce corneas for human transplant. An important part of their research has been conducted with a state-of-the-art bioreactor that was developed by Professor Ruberti’s group and commercialized by ADMET, Inc of Norwood, MA.

Topics: Biomedical, Laboratory research and consulting, bioreactor

Micro EP Used for Micro Tensile Testing of Plant Fibers

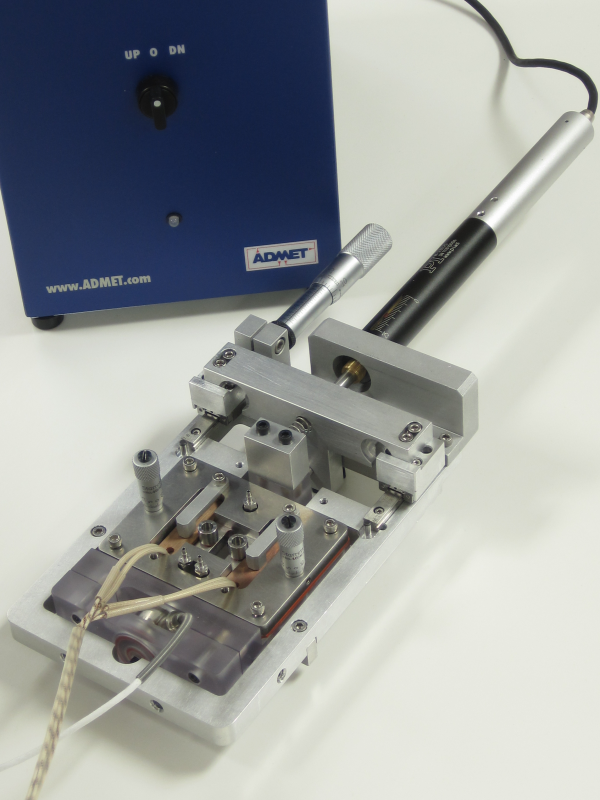

We recently worked with a leading research university that needed a system to test the tensile properties of plant fibers. Scientists at the university required a system that was capable of holding small wood fibers and testing them at extremely low forces. The testing system also needed to be compatible with a video microscope and had to be able to perform tests inside a liquid bath.

Topics: Biomedical, Tensile Test

ADMET Torsion System Chosen for Dental Screw Testing

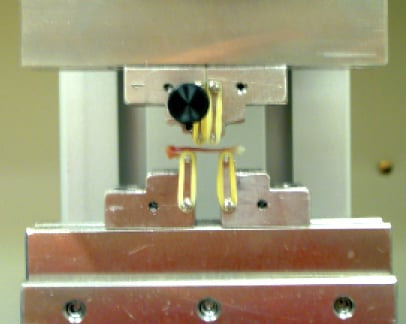

ADMET recently worked with a South East Asian medical device manufacturer that needed to conduct quality control tests on small metal screws used in dental applications. The company was looking for a system that could test the screws according to ASTM F543, a testing standard designed to check for product uniformity.

Topics: ASTM Tests, Biomedical, Torsion

ADMET Helps University Test Thin Film Solar Panel PVs

Imagine a window covered in solar panels that is still completley translucent or a jacket lined by solar panels that bend like fabric. ADMET recently worked with a leading university that was conducting research on a new type of photovoltaic (solar powered) film. These thin, flexible solar film could significantly expand our use of solar energy in the future.

Topics: Tensile Test, Plastics, Film, Bend Testing

Alaska Department of Fish and Game Tests Twine for Crab Pots Using ADMET eXpert System

The Alaska Department of Fish and Game (ADF&G) has broad responsibilities including oversight of the crab fisheries in Alaskan waters. A consequence of the pot gear used by the industry is a phenomenon called “ghost fishing,” which happens when functional pots are lost but continue to trap and kill crabs and other organisms. In response, regulations were enacted that require one sidewall of all crab pots have an opening that is secured with a biodegradable 100% cotton twine that would break down over time, fail and allow the trapped organisms to escape.

Topics: product development, Tensile Test, eP2 Digital Controller, Laboratory research and consulting, eXpert 5600, textiles and fibers

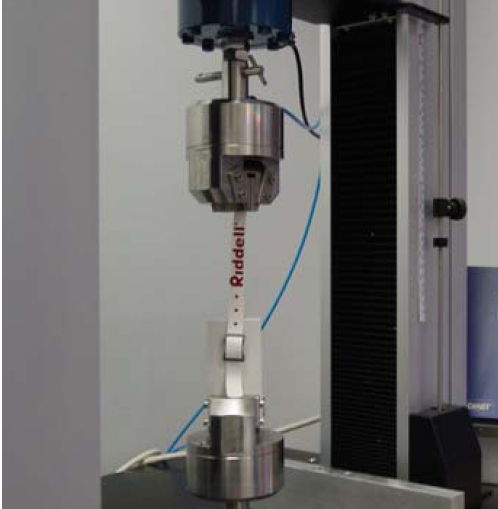

Riddell Uses ADMET’s Multiple Plot and Graphics Capabilities

Riddell, a subsidiary of Easton-Bell Sports, is known primarily for its quality football helmets used by the NFL, college and high school teams. Its reputation is well-deserved since the company developed the first plastic suspension helmet in 1939 and has continually improved on the design ever since. The company rigorously tests materials and components before they are certified to be used in its products.

Topics: MTESTQuattro, product development, Plastics, eXpert 2600

X-Spine Uses ADMET eXpert 5601 for Development and Quality Testing

X-spine Systems, Inc. is a next-generation spinal implant company dedicated to advancing spinal implant technologies that improve surgery outcomes and optimize surgeon experience.

Topics: product development, Biomedical, eP2 Digital Controller, eXpert 5600

University of Michigan Researchers Use ADMET to Test Mechanical Properties of Bone

A University of Michigan research laboratory is conducting mechanical testing of bone to measure its mechanical properties. Led by Prof. David Kohn, the lab conducts destructive tests that flex the bone to failure in a four-point bend fixture. Their research calls for a system that can accurately control the deflection rate, and generate a flexural stress versus strain curve. Another test results in a cyclic control profile in which the specimen is cycled between two defined values at a frequency of one Hertz for two hours.

Topics: MTESTQuattro, product development, Biomedical, University, Laboratory research and consulting, eXpert 5600, Flexural testing

McMaster University Uses eXpert 5600 to Test the Flexural Strength of Bone

The Department of Mechanical Engineering at McMaster University of Hamilton, Ontario recently began conducting biomechanical research. The projects, under the direction of Assistant Professor Greg Wohl, PhD, studies the effects of mechanical loading on bone through compression and flexure testing. The University had not conducted this type of research and, although well-equipped for mechanical testing, some new equipment was required.

Topics: Biomedical, eP2 Digital Controller, University, eXpert 5600, Flexural testing