There are multiple costs associated with purchasing and operating a materials testing machine. Before you begin testing, not only do you need to consider the purchase price of the machine, but shipping, installation and site modification costs as well. Shipping costs my run between $500 to $2,500 or more depending on size and weight,. If the machine is large and your facility has no clear route between the loading dock and test lab, then you may need to hire a rigger to uncrate the tester and transport the machine to the lab. Rigging costs vary greatly depending on issues like having to traverse stairs or remove a door or window. Prior to placing the machine in the lab, you must also determine if the floor is rated to support the weight of the machine and if you have the required electrical power installed in the room.

Topics: universal testing machine, University

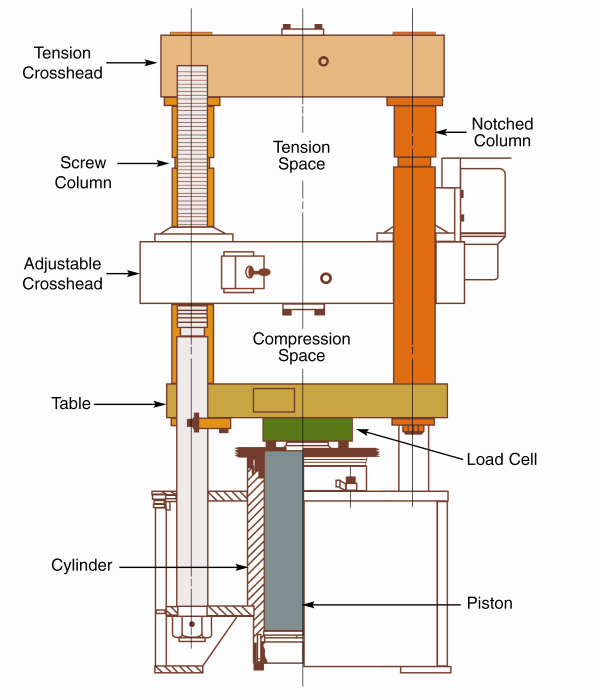

The Wikipedia entry for a Universal Testing Machine (UTM) defines it as: “A universal testing machine is used to test the tensile stress and compressive strength of materials. It is named after the fact that it can perform many standard tensile and compression tests on materials, components, and structures.” This is very true, but perhaps overly simplistic. We’ll try to explain some more capabilities of these machines in this post.

Topics: Peel, Compression Test, universal testing machine, Tensile Test, Bend Testing, puncture testing

Do I retrofit or replace my hydraulic universal testing machine?

What do you do when your outdated hydraulic materials testing machine breaks or your customer requires a test that cannot be performed with your existing system? Do you replace the testing system with a new one or do you upgrade/retrofit with new software and controls?

Topics: Retrofit, Servo Hydraulic, universal testing machine, eP2 Digital Controller, University, Servo-Automatic Control

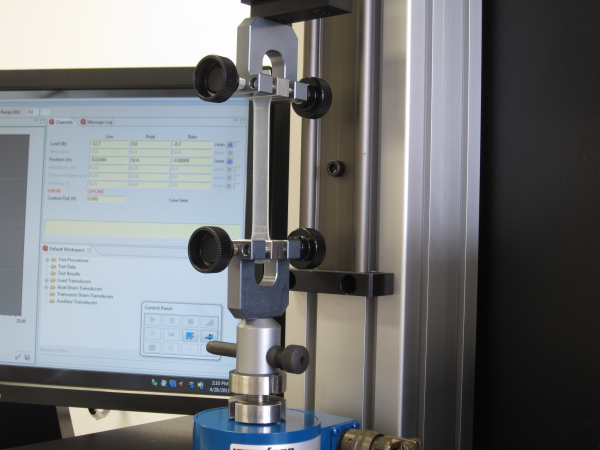

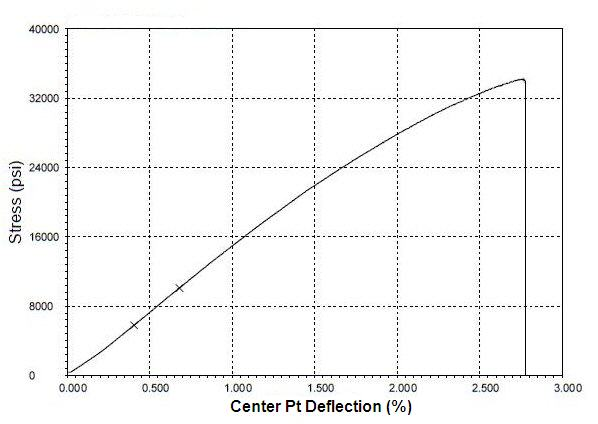

A universal testing machine is used to measure the mechanical properties of materials in tension, compression, bending or torsion. Mechanical properties of interest for plastics in bending are Flexural Strength, Flexural Stress at Break, Tangent, Secant and Chord Modulus of Elasticity. ASTM D790 Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials governs the flexural testing of plastics. In bending, a testing machine is used to create a stress-strain diagram (Figure 1) from which all mechanical properties are derived. A true picture of the stress-strain diagram can only be obtained through accurate measurements.

Topics: universal testing machine, University, Flexural testing, Extensometer

ASTM E8 - Measuring the Tensile Strength of Metals

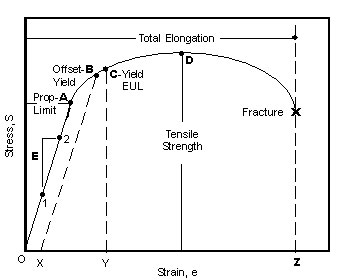

Tension tests provide information on the strength and ductility of metals under uniaxial tensile stresses. ASTM E8 Standard Test Methods for Tension Testing of Metallic Materials specifies how to perform the strength and ductility tests for metals. Strength refers to the ability of a structure to resist loads without failure due to excessive stress or deformation. Ductility is a measure of a metals ability to deform under tensile stresses. Ductility is important in metal forming processes, as metals that crack or break under stress cannot be manipulated by hammering, rolling or drawing.

Topics: Tensile Test, metal

How to perform a Thread Tensile Test on an eP2 Controlled Testing System

If you seek to learn about thread tensile testing or the ASTM D2256 test method, please read this article. This page assumes you understand the test and you already own an an ADMET universal testing machine preloaded from the factory with this test method installed. Good luck, and call us should you have any questions.

Topics: ASTM Tests, Textile, universal testing machine, Tensile Test, University

How to set up an ASTM D1876 Test on an eP2 controlled Testing Machine

If you seek to learn about the ASTM D1876 T-Peel adhesive peel test, please read this article. This page assumes you understand the test and you already own an an ADMET universal testing machine. If your machine came preloaded from the factory with this test method installed, you can skip the "how to program" video. Good luck, and call us should you have any questions.

Topics: Peel, ASTM Tests, Adhesive

How to set up an ASTM D882 Test using an eP2 Controlled System

If you seek to learn about the ASTM D822 tensile & elongation test, please read this article. This page assumes you understand the test and you already own an an ADMET universal testing machine. If your machine came preloaded from the factory with this test method installed, you can skip the "how to program" video. Good luck, and call us should you have any questions.

Topics: ASTM Tests, Film

How to set up an ASTM D1894 Test on an eP2 controlled Testing System

If you seek to learn about the ASTM D1894 coefficient of friction test (COF), please read this article. This page assumes you understand the test and you already own an ADMET universal testing machine and COF fixture. If your machine came preloaded from the factory with the COF test method installed, you can skip the "how to program" video. Good luck, and call us should you have any questions.

Topics: ASTM Tests, Film, Friction

Materials Testing Mechanical Properties Glossary

In the field of materials testing, there are certain words and phrases that must be understood in order to correctly assess the properties of any given material. This guide will provide you with a quick reference for any terms that may be unfamiliar.

Topics: University